Subject_05_Final Mov

The final prototype's name is "SEAT". It means making seat and this chair will make the act to sit in this seat (sit;seat). Anyway this is the final movie working model and final exhibition in degree show. And thanks to my professor David hall for many and great advices.

"SEAT"

Monday, December 8, 2014

Saturday, November 15, 2014

Exp_05_13

Subject_05_Assembling

The first step for assembling is bonding vertical structure to sustain weight. The vertical structure is made with bonded each other three plates. The middle plate has structure like a bone, so 12 vertical plates can sustain very heavy weight.

Mid structure

Bonding

The fixing parts to assemble skin and gear parts need tapping process because these parts need strong union. These parts are combined by bolts directly. And at first, the top floor is assembled.

Installed arduino board

Rack gear test

The circuit board will be placed on bottom plate, so the model is turned over for completely assemble. The bottom plate and circuit board are hang on the celling with fishing wire and whole wiring proceeds.

After wiring and assembling body structure, silicon skins are installed. Whole silicon skins are divided into four parts and each parts are connected through prepared point to have same height from body parts. And silicon is installed on body part by tapped acrylic parts and bolt.

Tapped parts and bolt

Test_02

Test_03

The first step for assembling is bonding vertical structure to sustain weight. The vertical structure is made with bonded each other three plates. The middle plate has structure like a bone, so 12 vertical plates can sustain very heavy weight.

Mid structure

Bonding

Installing servo

The fixing parts to assemble skin and gear parts need tapping process because these parts need strong union. These parts are combined by bolts directly. And at first, the top floor is assembled.

Fixing parts for skin

Gear

Installed gear

Rack gear

Installed arduino board

Assembled top floor

Rack gear test

The circuit board will be placed on bottom plate, so the model is turned over for completely assemble. The bottom plate and circuit board are hang on the celling with fishing wire and whole wiring proceeds.

Turning over

Hanged botom plate

Wiring circuit

After wiring and assembling body structure, silicon skins are installed. Whole silicon skins are divided into four parts and each parts are connected through prepared point to have same height from body parts. And silicon is installed on body part by tapped acrylic parts and bolt.

Tapped parts and bolt

Installing skin

Installed skin

Completed model

Test_01

Test_02

Test_03

Exp_05_12

Subject_05_Preparing Whole parts

For the final model, whole parts are prepared by laser cut method. And the mould is made by acrylic material also. Actually the silicon material skin will be made by hand casting without mould using viscosity controller. But if there is no mould, the surface of skin will be tough. So the method is changed for clear surface with completely quality.

Laser cutting_01

Laser cutting_02

Whole parts

Connecting part

The body parts need the process that whole parts are sanded surface for making glass material texture. Gears, rails, racks, structures and plates are all sanded at specialty shop.

For the final model, whole parts are prepared by laser cut method. And the mould is made by acrylic material also. Actually the silicon material skin will be made by hand casting without mould using viscosity controller. But if there is no mould, the surface of skin will be tough. So the method is changed for clear surface with completely quality.

Laser cutting_01

Laser cutting_02

Whole parts

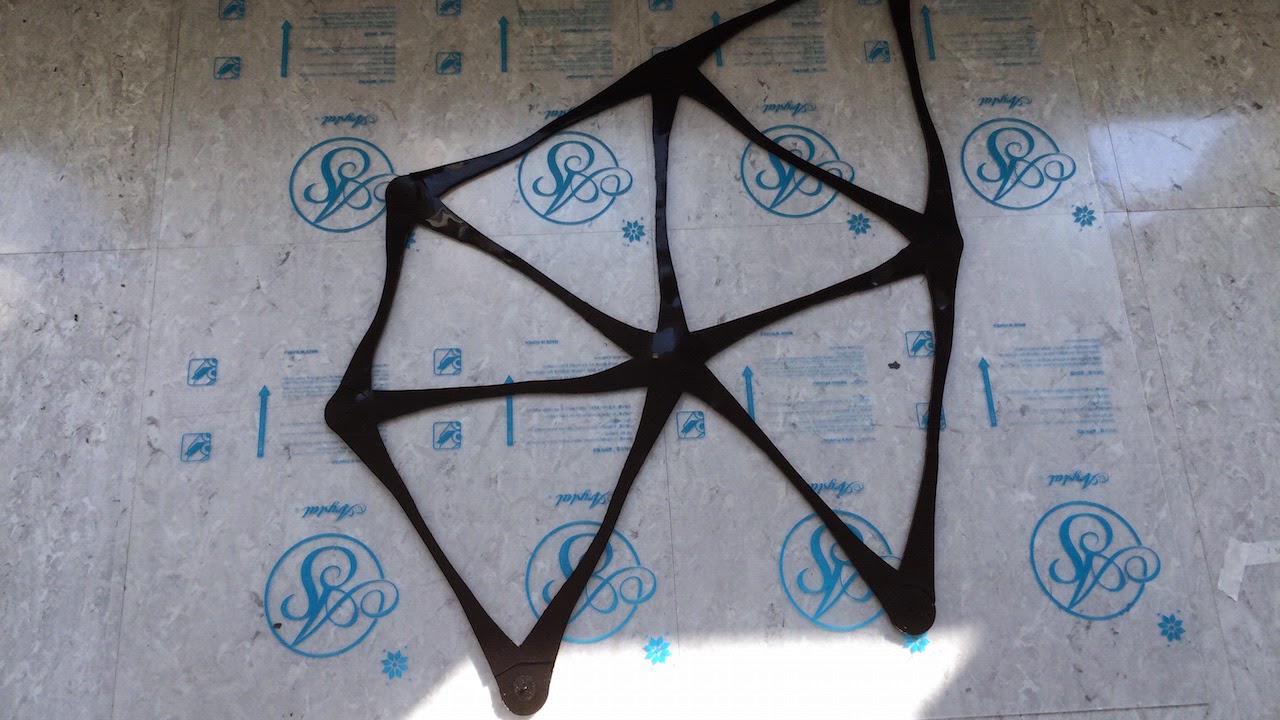

The skin schematic shape is made by 3d modeling and this model is transformed to planar figure by pepakula program. This planar figure is used for making skin silicon mould. Silicon skin will have 5mm thickness and 85% scale in comparison with original skin size for sustaining weight.

Planar figure

Mould

Acrylic bond

The silicon color will be black color. The black dye for silicon will be used and the color can express contrast and emphasis feeling for skin wire frame shape in comparison with white acrylic body.

Black color dye for silicon

Mix

Casting

Pull out & Clear edge

Completed skin

The body parts need the process that whole parts are sanded surface for making glass material texture. Gears, rails, racks, structures and plates are all sanded at specialty shop.

Whole body parts

Sanding

Completed sanding

Thursday, October 23, 2014

Exp_05_11

Subject_05_Module test for skin material_02 & Sensor test

The skin surface needs more elastic and stretchable material for natural movement. So, the silicon is used for test in this time experiment. The silicon is originally used for special cosmetic in movie field. For example, making skin or the flesh of body and so on. This silicon has 800% stretch possibility and is very durable. Let's test.

Eco Flex 0010 from Smoth on company

Mix

Test

Stretching test

The test is very successful. The silicon is very soft and durable when it is fully casted. But, the silicon needs more thicker for making shape in model surface. So, the viscosity controller is needed. And module surface is tested with two shape type. The one has inside wire like an web, and the other is made by just wire frame. In addition this, the sensor is added for making interactive environment. The PIR sensor is installed to find human motion and TCRT5000 is installed to find sitting person on the top floor of chair.

Web type

Circuit for sensors

First test

Wire frame type

Cast without mould

Connection with module

Second test

Movie

The skin surface needs more elastic and stretchable material for natural movement. So, the silicon is used for test in this time experiment. The silicon is originally used for special cosmetic in movie field. For example, making skin or the flesh of body and so on. This silicon has 800% stretch possibility and is very durable. Let's test.

Eco Flex 0010 from Smoth on company

Mix

Test

Stretching test

The test is very successful. The silicon is very soft and durable when it is fully casted. But, the silicon needs more thicker for making shape in model surface. So, the viscosity controller is needed. And module surface is tested with two shape type. The one has inside wire like an web, and the other is made by just wire frame. In addition this, the sensor is added for making interactive environment. The PIR sensor is installed to find human motion and TCRT5000 is installed to find sitting person on the top floor of chair.

Thi-vex viscosity controller

Vinyl for mould

Web type

Circuit for sensors

First test

Wire frame type

Cast without mould

Connection with module

Second test

Movie

Sunday, October 19, 2014

Exp_05_10

Subject_05_Module test for skin material_01 & Tech test

The module making is needed for skin material choice. So, the part of first floor in whole model is chosen for module test. The part is triangle shape and it has three vertices with 3 servos with real scale. And whole parts are made by laser cutting method through cad drawing. Actuators are using 6 voltage and they have the 11kg/cm torque in 6 voltage.

Assembling_01

Assembling_02

Gear and Servo

Rack for linear movement

The top for sitting part

Gear movement

The first material is elastic wire and fabric. The elastic wire is for fastening long hair and fabric is woman's black stockings. Actually, these materials are too tight to sustain the tension for servo. So, something new material is needed to perfectly work in final model. This is the first test mov.

Black stocking

Material test_01

Before the final model making, the project needs confirmation to working multiple servo with one signal between vvvv and arduino. So, the technical test is processed at first. Two arduino boards are used, and 16 servos are used. Each 4 servos are connected with 6 voltage 2A AC/DC convertor, so 4 AC/DC convertors are used totally by external power source in this circuit. This is the test movie.

Tech test

The module making is needed for skin material choice. So, the part of first floor in whole model is chosen for module test. The part is triangle shape and it has three vertices with 3 servos with real scale. And whole parts are made by laser cutting method through cad drawing. Actuators are using 6 voltage and they have the 11kg/cm torque in 6 voltage.

Whole parts

Assembling_01

Assembling_02

Gear and Servo

Rack for linear movement

The top for sitting part

Gear movement

The first material is elastic wire and fabric. The elastic wire is for fastening long hair and fabric is woman's black stockings. Actually, these materials are too tight to sustain the tension for servo. So, something new material is needed to perfectly work in final model. This is the first test mov.

Elastic wire

Black stocking

Material test_01

Before the final model making, the project needs confirmation to working multiple servo with one signal between vvvv and arduino. So, the technical test is processed at first. Two arduino boards are used, and 16 servos are used. Each 4 servos are connected with 6 voltage 2A AC/DC convertor, so 4 AC/DC convertors are used totally by external power source in this circuit. This is the test movie.

Two Boards

16 Servos

4 AC/DC Convertors

6V 2A Adaptor

Whole circuit

Tech test

Subscribe to:

Comments

(

Atom

)